At TouchScreenMan, we believe that every customer should have access to the best possible touch screen solutions for their needs. That’s why we’re committed to providing custom resistive touch screens that are designed to meet the specific requirements of each application, with a focus on quality, reliability, and affordability.

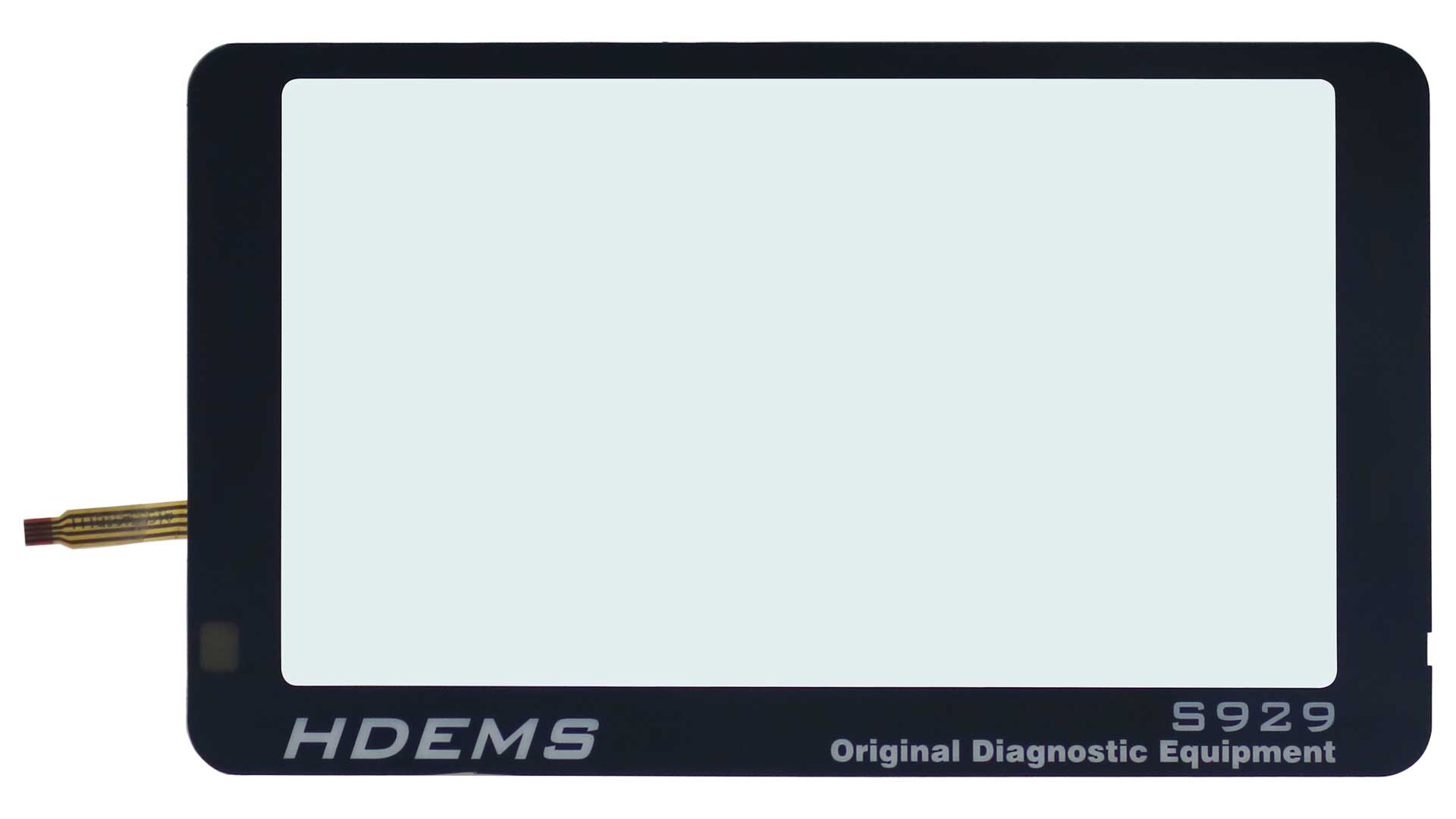

Analog Resistive Touch Screen

The common, newer and cost saving resistive touch technology. It has a variety types: 4-wire, 5-wire, 8-wire, etc.

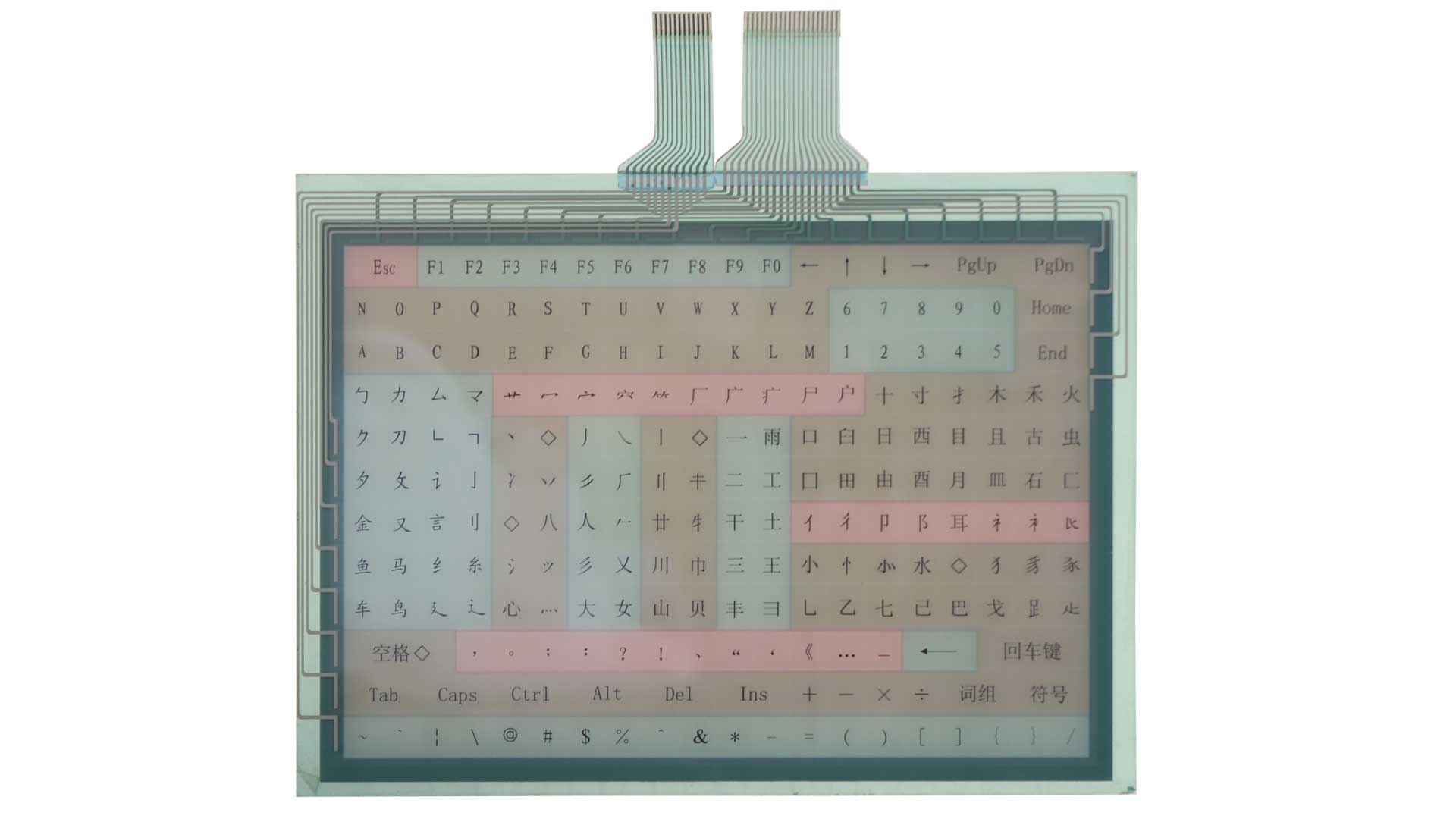

Digital Matrix Resistive Touch Screen

It not only has all the merits of analog 4-wire resistive touch screen, but also is extremely accurate. No deviation.

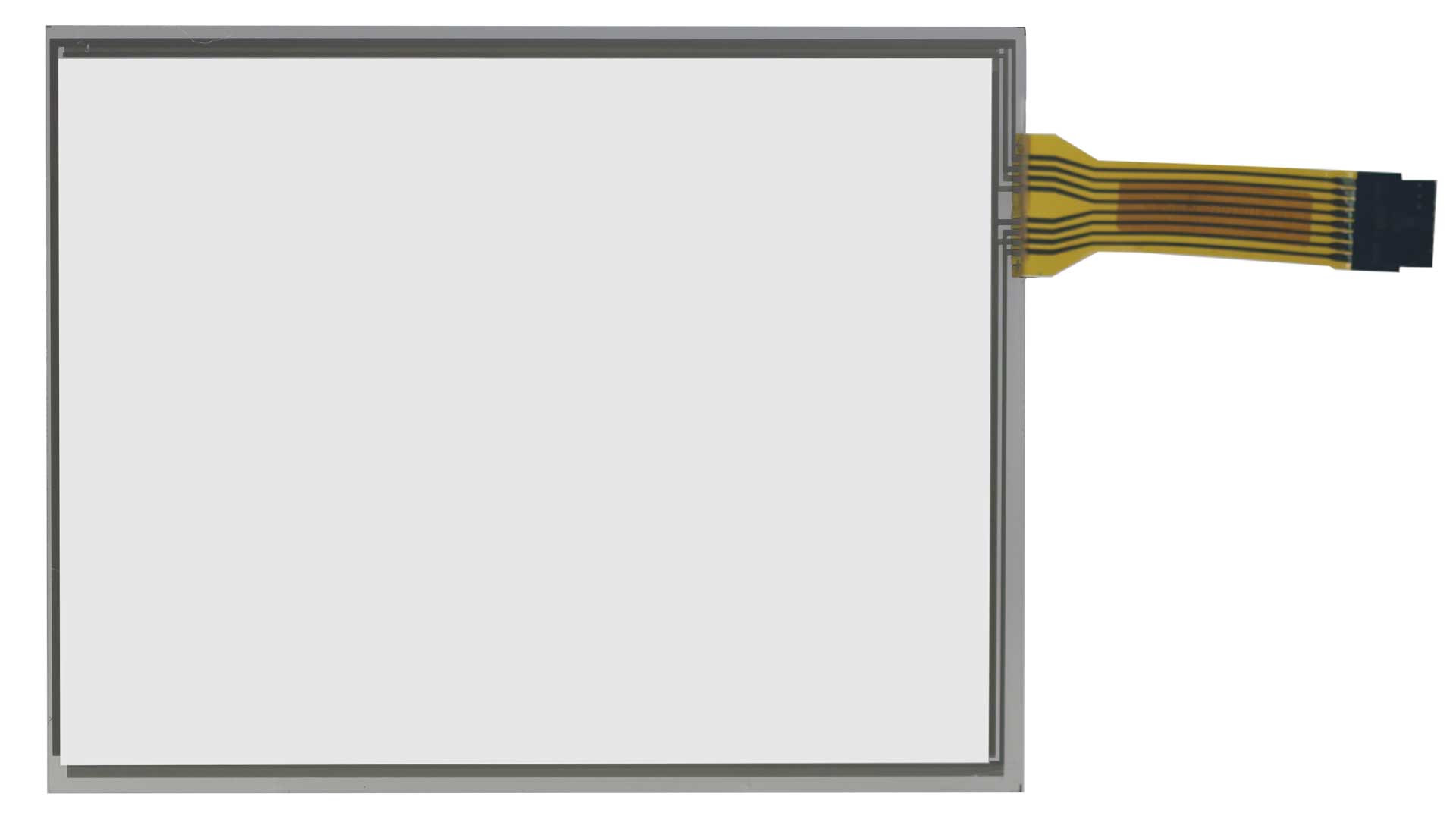

2-Layer Resistive Touch Screen

The most basic and widest used structure of all the resistive touch screens

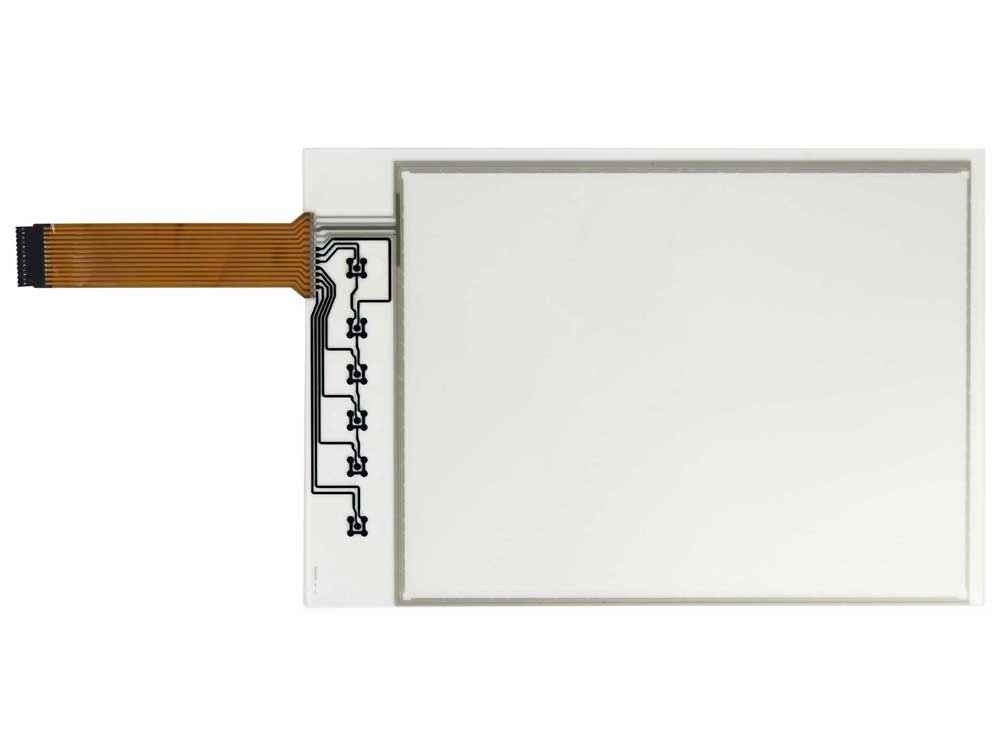

3-Layer Resistive Touch Screen

One more decorated layer or supporting layer than 2-layer resistive touch screen.

4-Layer Resistive Touch Screen

It has both decorated layer and supporting layer.