Don’t settle for a generic, off-the-shelf switch. Choose TouchScreenMan for a custom solution that is designed to meet your specific needs. Contact us today to learn more about our custom membrane switch services.

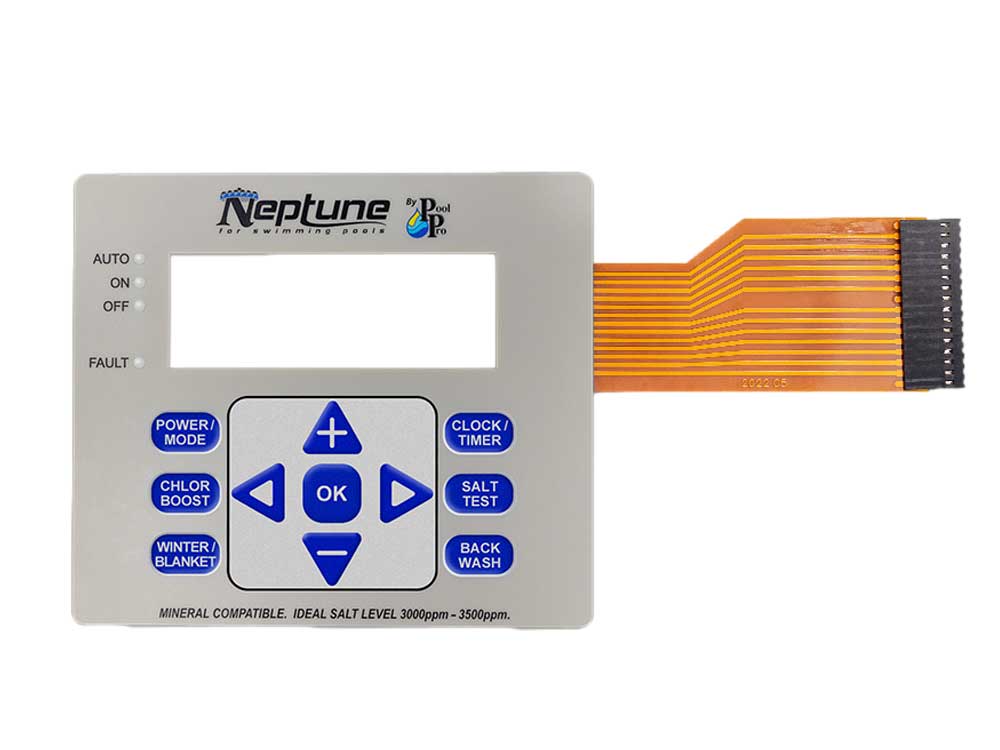

PET Circuit Membrane Switch

PET’s primary advantages include its cost-effectiveness and flexibility, making it an ideal choice for projects with limited budgets.

FPC Circuit Membrane Switch

Higher reliability,Resistance to vibration and extreme temperatures, Surface-mount component compatibility, but with a Higher cost.

Silicone Button Membrane Switch

Silicon Button Membrane Switches take user experience to new heights with haptic feedback through tactile metal domes or poly-dome construction.

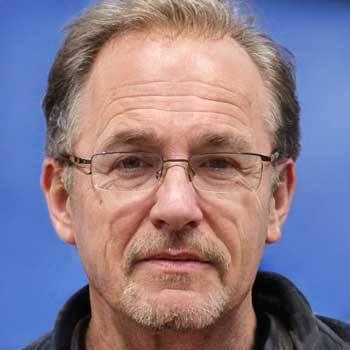

Medical Anti-bacterial Membrane Switch

Medical Anti-bacterial Membrane Switches are innovative solutions that enhance the hygiene and safety of medical devices. These membrane switches feature antibacterial, water-resistant, and dust-proof properties.

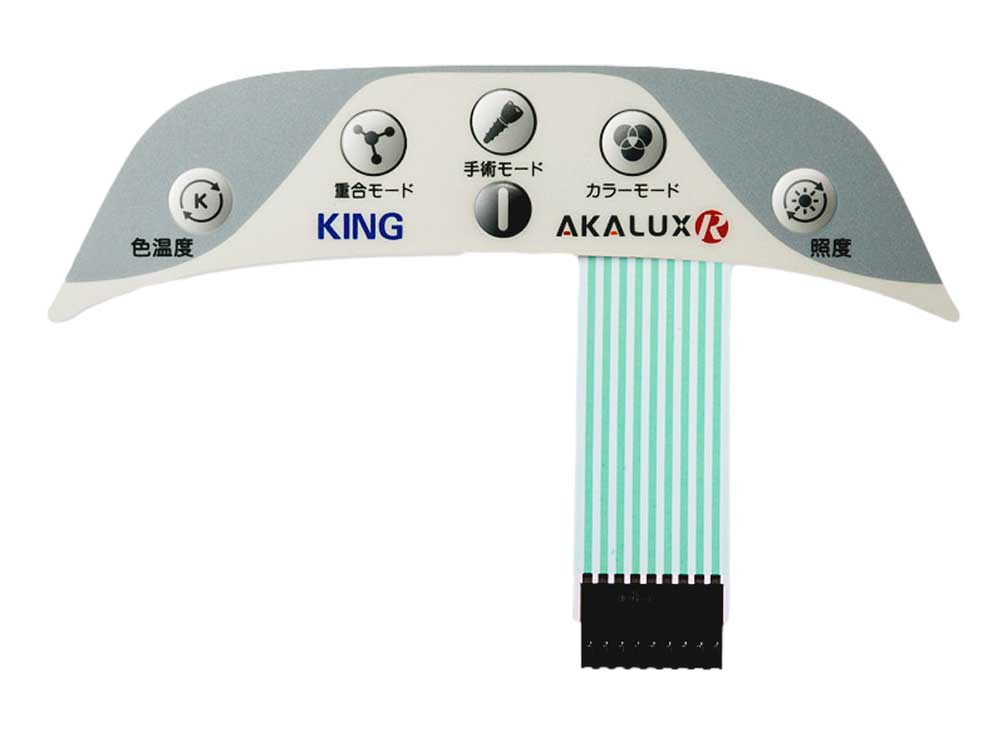

Waterproof And Dustproof Membrane Switch

A waterproof and dustproof membrane switch is a remarkable evolution of the traditional membrane switch, specifically designed to withstand harsh environments.

LED Lighting Membrane Switch

First up, the Leonardo of light – the LED emitting layer, sitting pretty as a distinct layer within the switch itself. Then, enters the frugal Van Gogh – the external LED backlight or lamps on PCB.