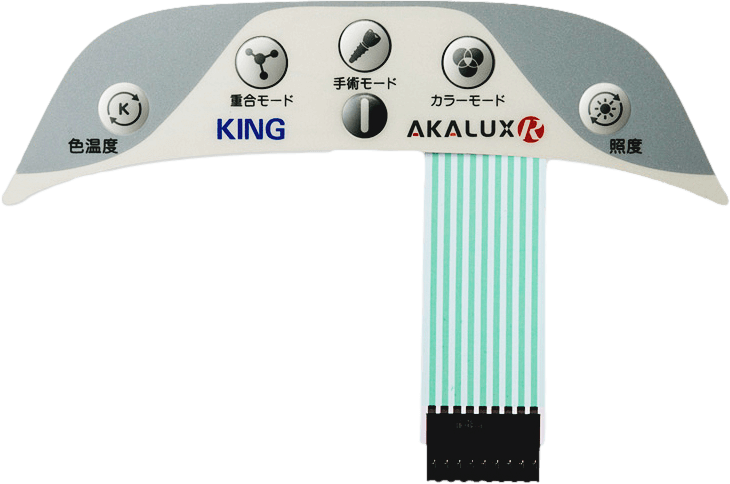

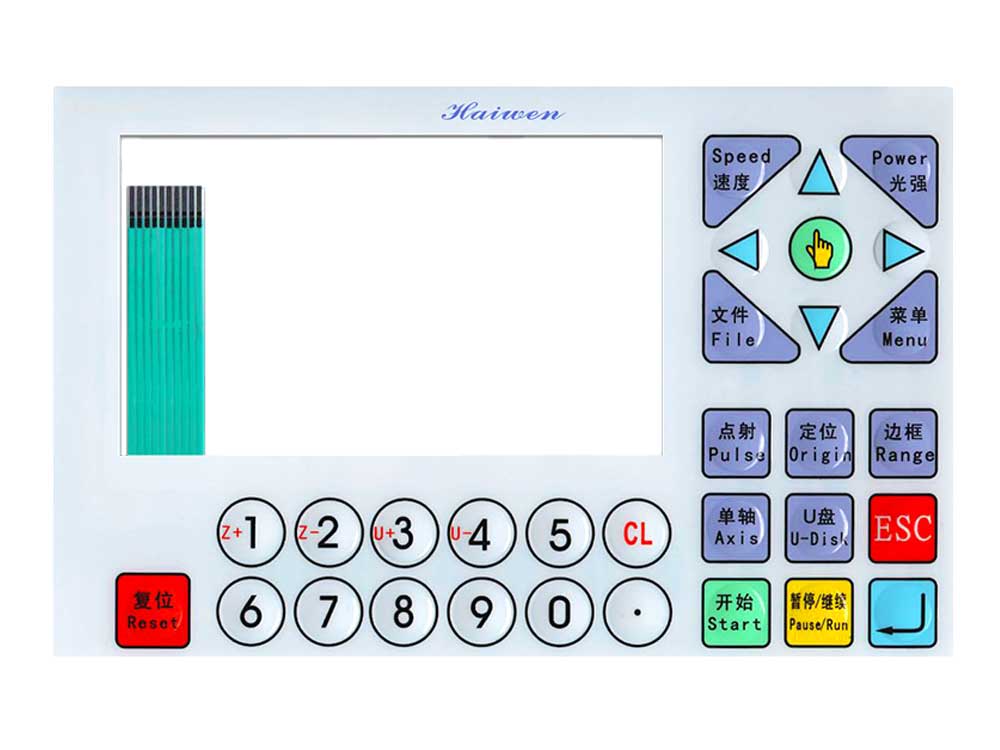

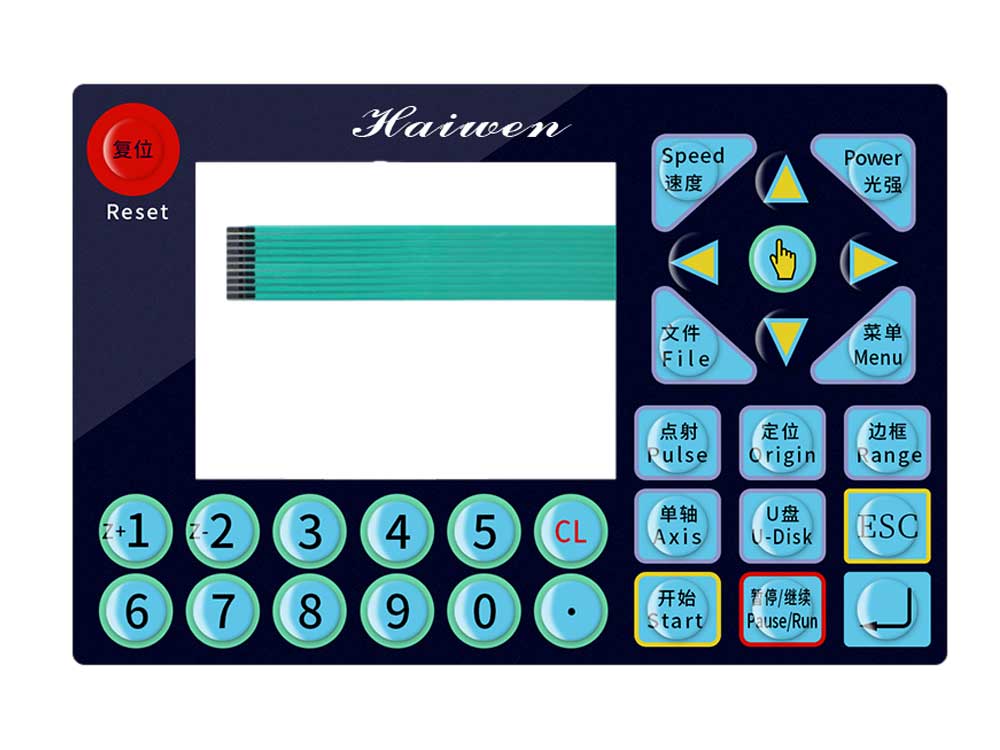

Polyethylene terephthalate (PET), a versatile material utilized in various applications ranging from food packaging to electronic components, is widely recognized for its crucial role in flexible circuits for membrane switches in electronics. Membrane switches, integral to Human Machine Interfaces (HMI) and instrumental in industrial control systems, primarily rely on PET as a foundation. In this article, we delve into the nitty-gritty of PET’s use in flexible circuits, scrutinizing its pros and cons in comparison to other materials such as Flexible Polymer Circuits (FPC).