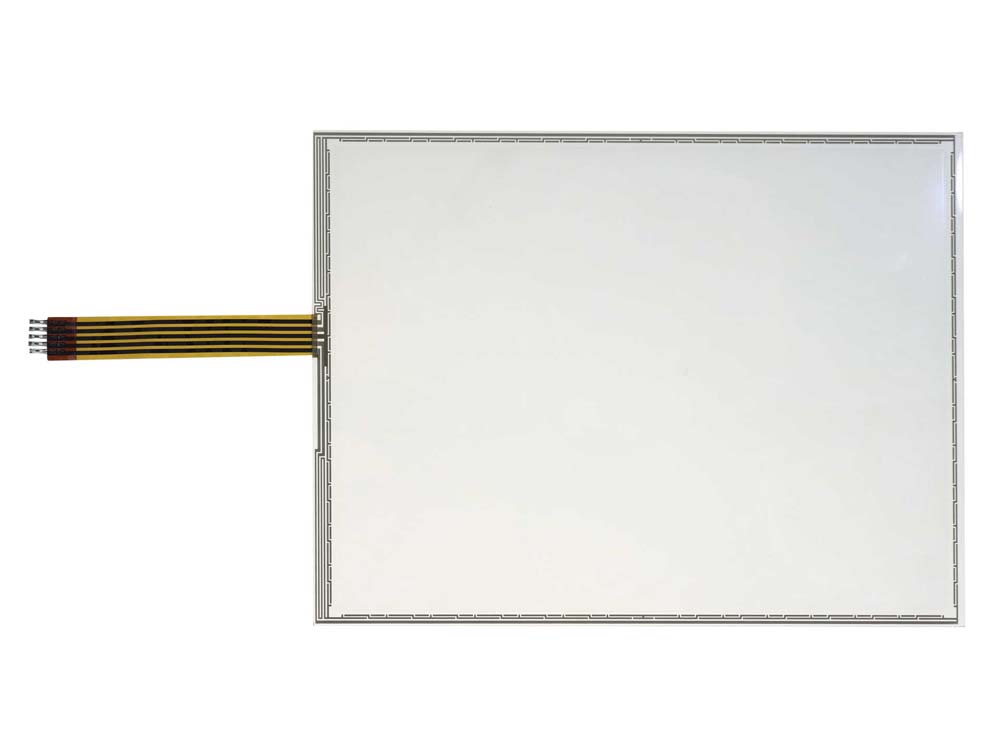

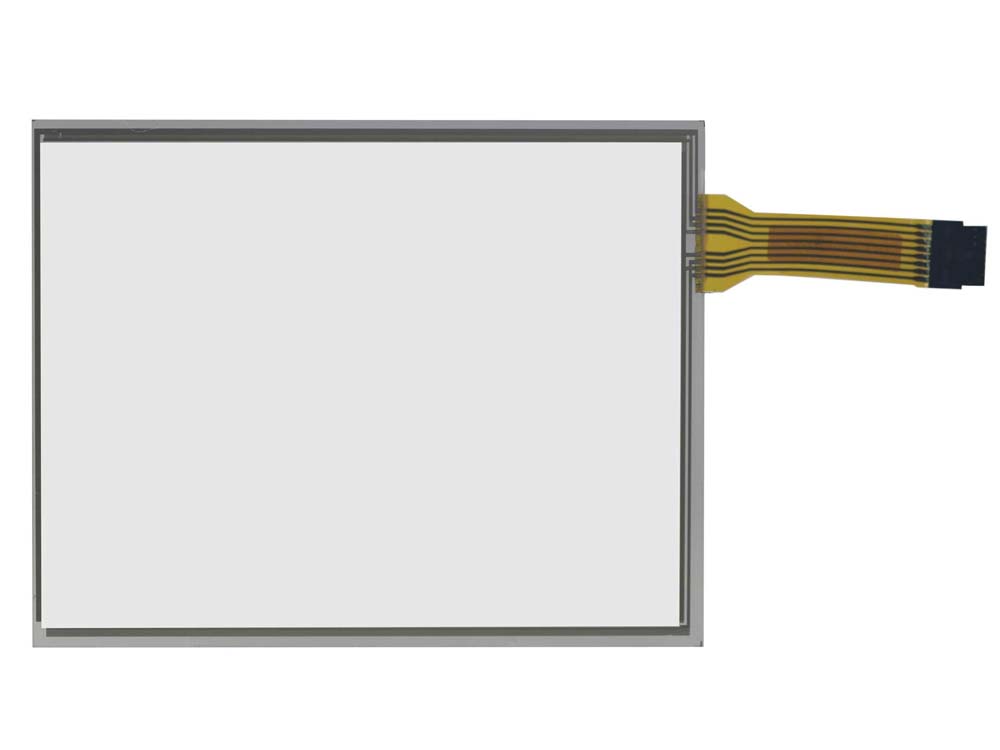

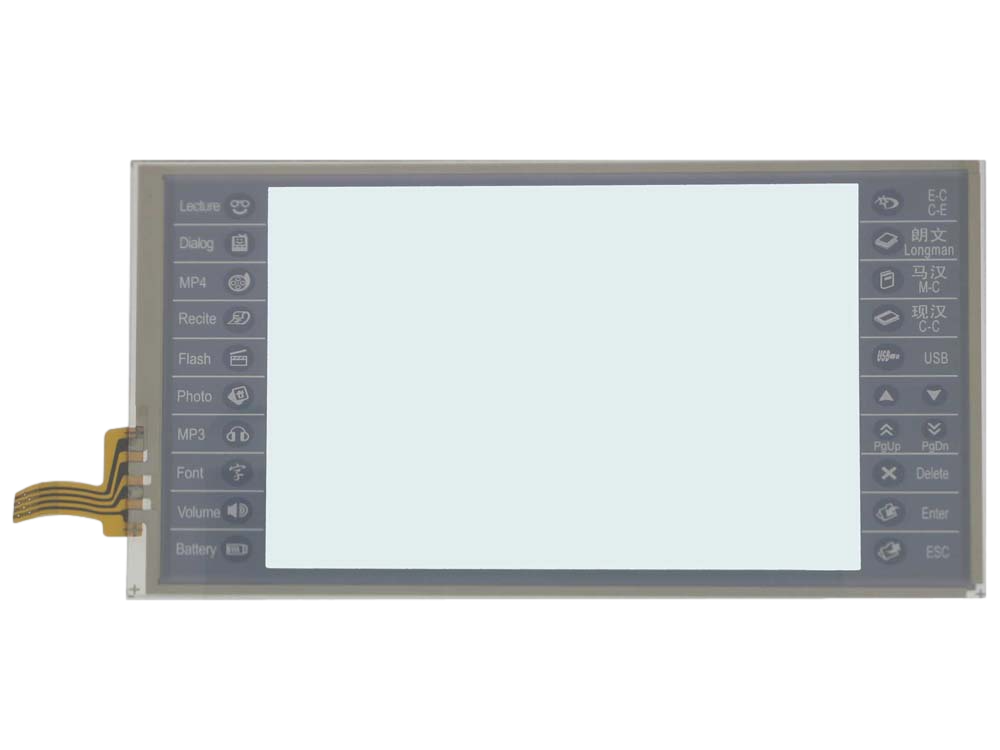

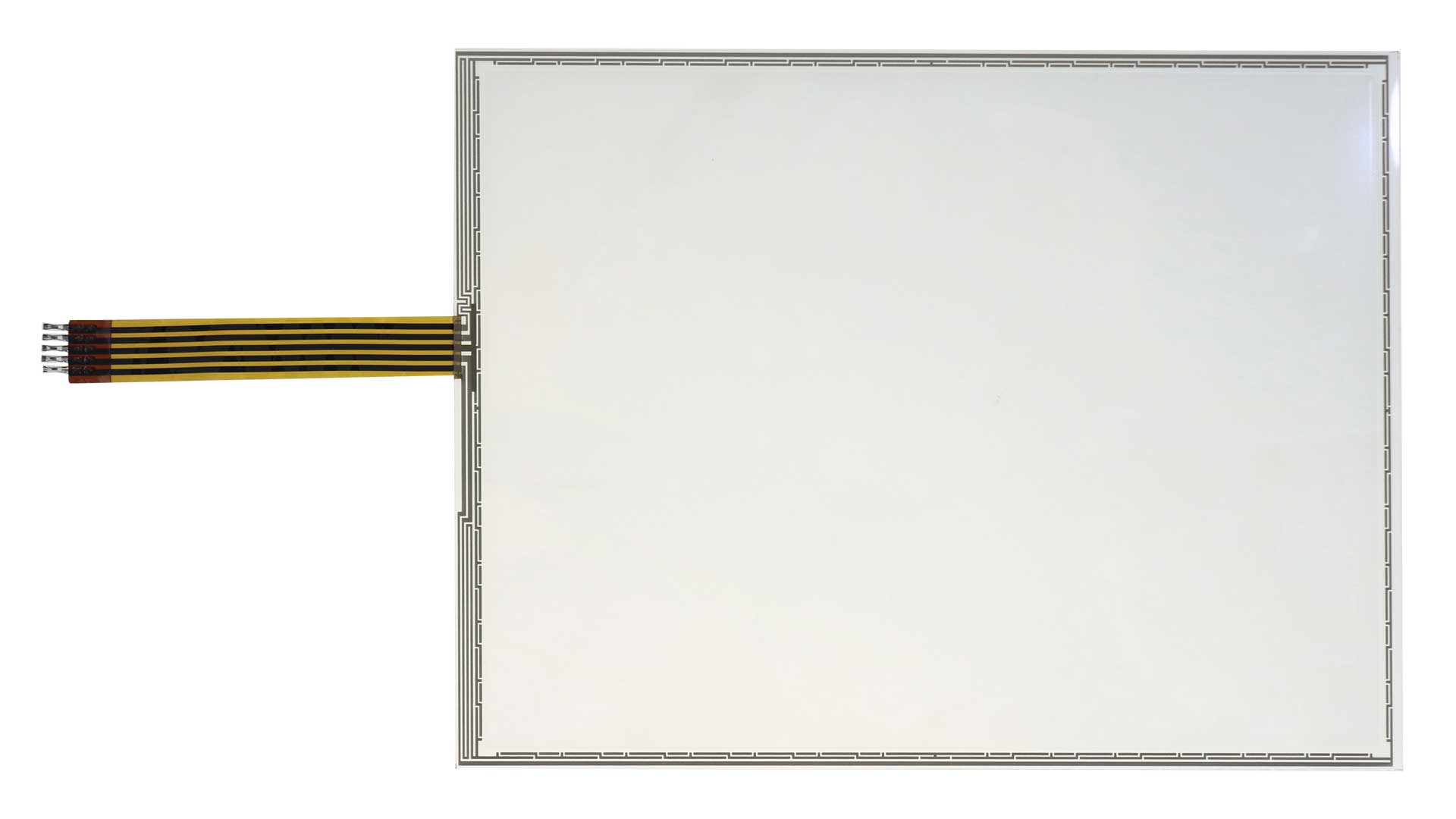

Custom analog resistive touch screens differ from other touch screen technologies as Digital Matrix Resistive Touch Screen in several ways. One of the main differences is the number of wires used in their construction. Custom analog resistive touch screens typically use fewer wires, such as 4-wire, 5-wire, or 8-wire, to connect the touch screen to the device. This results in less space being required for the wires on the frame, making the overall design more compact and streamlined.

Another difference is the number of touch points that can be registered on the screen. Unlike digital matrix resistive touch screen technologies, custom analog resistive touch screens can register countless touch points using only a few wires. This makes them a more efficient and effective solution for touch screen technology.

Overall, the use of fewer wires and the ability to register countless touch points make custom analog resistive touch screens unique from digital matrix resistive touch screen technologies. These features make them a popular choice for various applications where space and design are important considerations.