At the end of the day, investing in high-quality Custom Capacitive Touch Screens can make a significant difference in the success of your device or application. That’s why it’s crucial to work with a reputable and experienced touch screen manufacturer like TouchScreenMan.

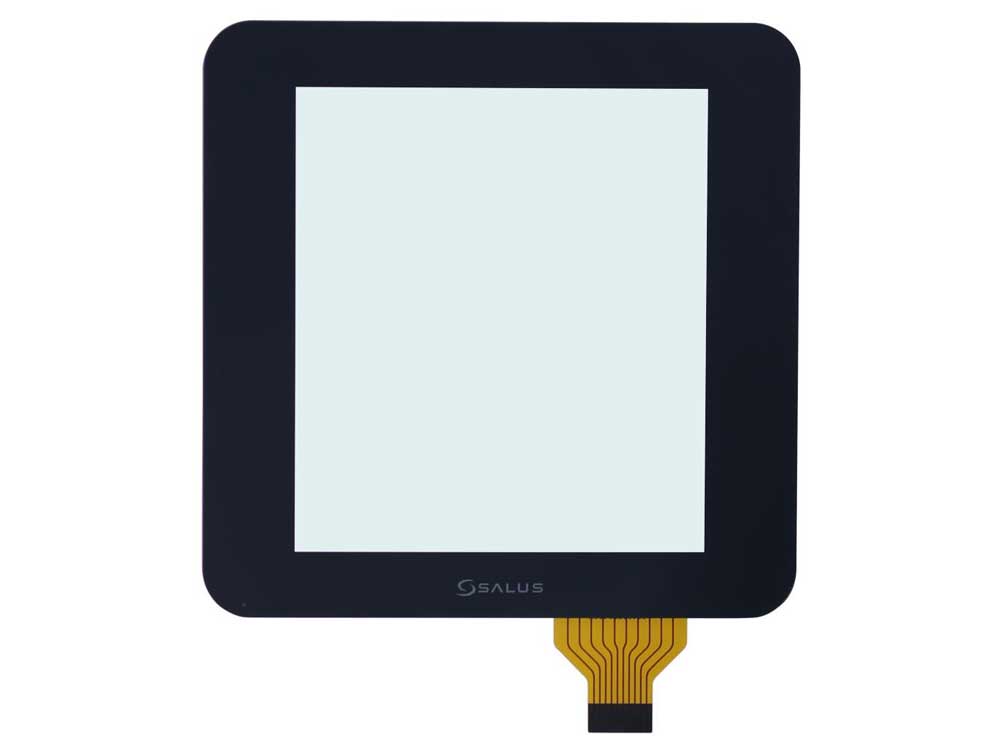

Surface Capacitive Touch Screen

Relatively low cost, simple working principle and simple design circuit, but easily affected by the environments, difficult to achieve multi-touch.

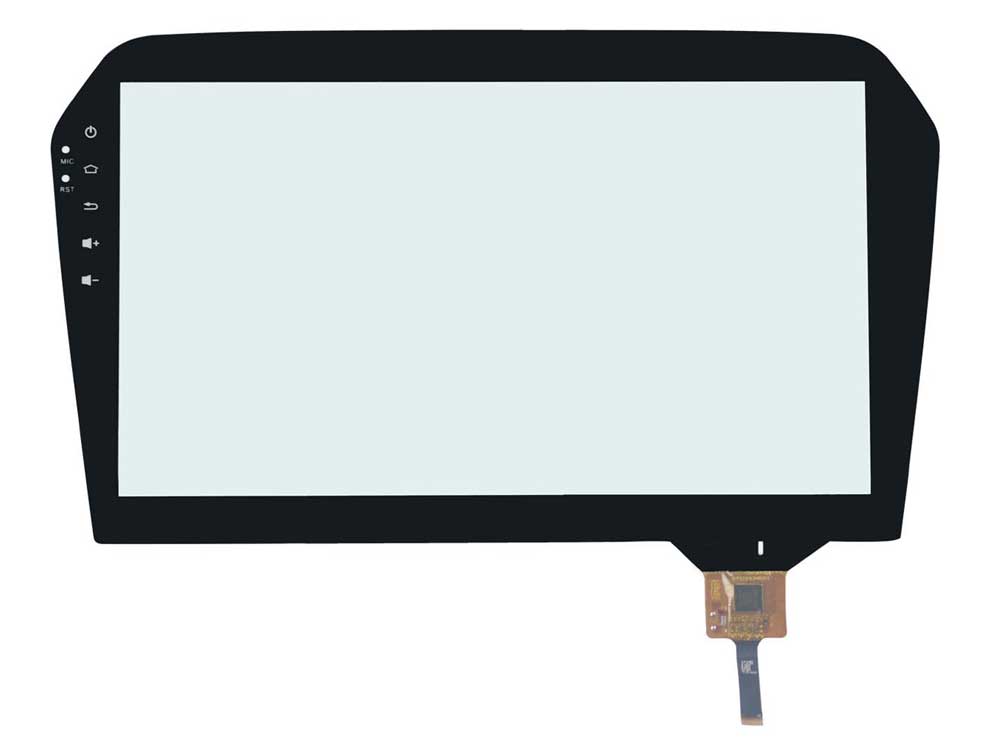

Projected Capacitive Touch Screen

Relatively high cost, complicated strcture, one or two dedicated designed and etched ITO layers to achieve the touch function.

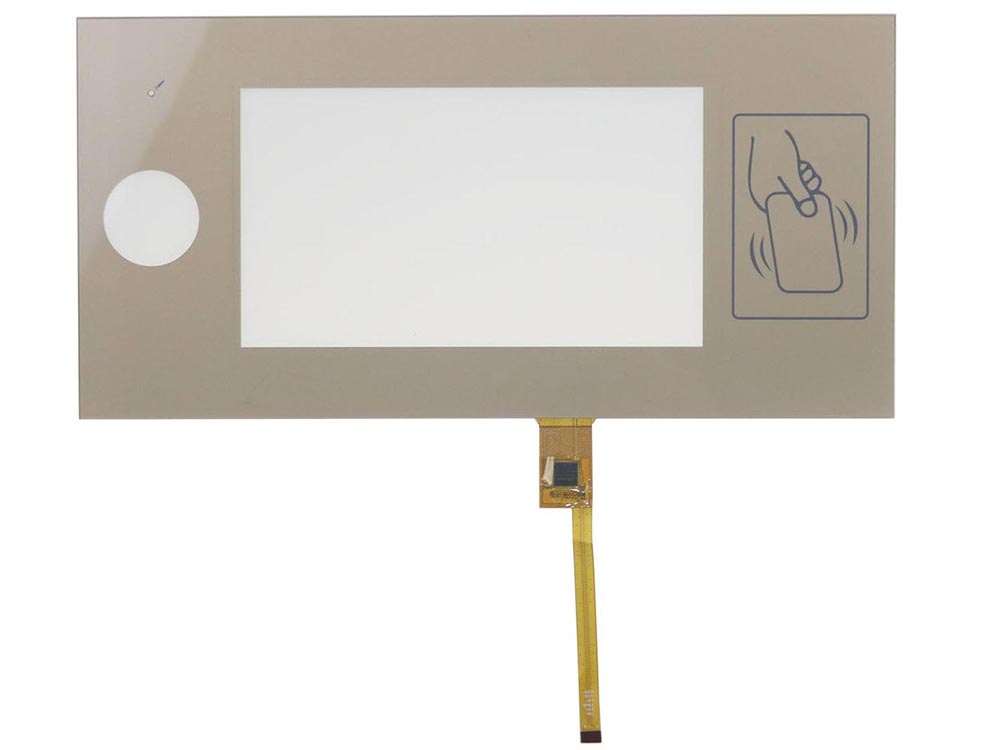

Capacitive Touch Sensor Film Switch

Simplified version of surface capacitive touch screen. Lowest cost, simple structure and single touch.