What is a Digital Matrix Resistive Touch Screen

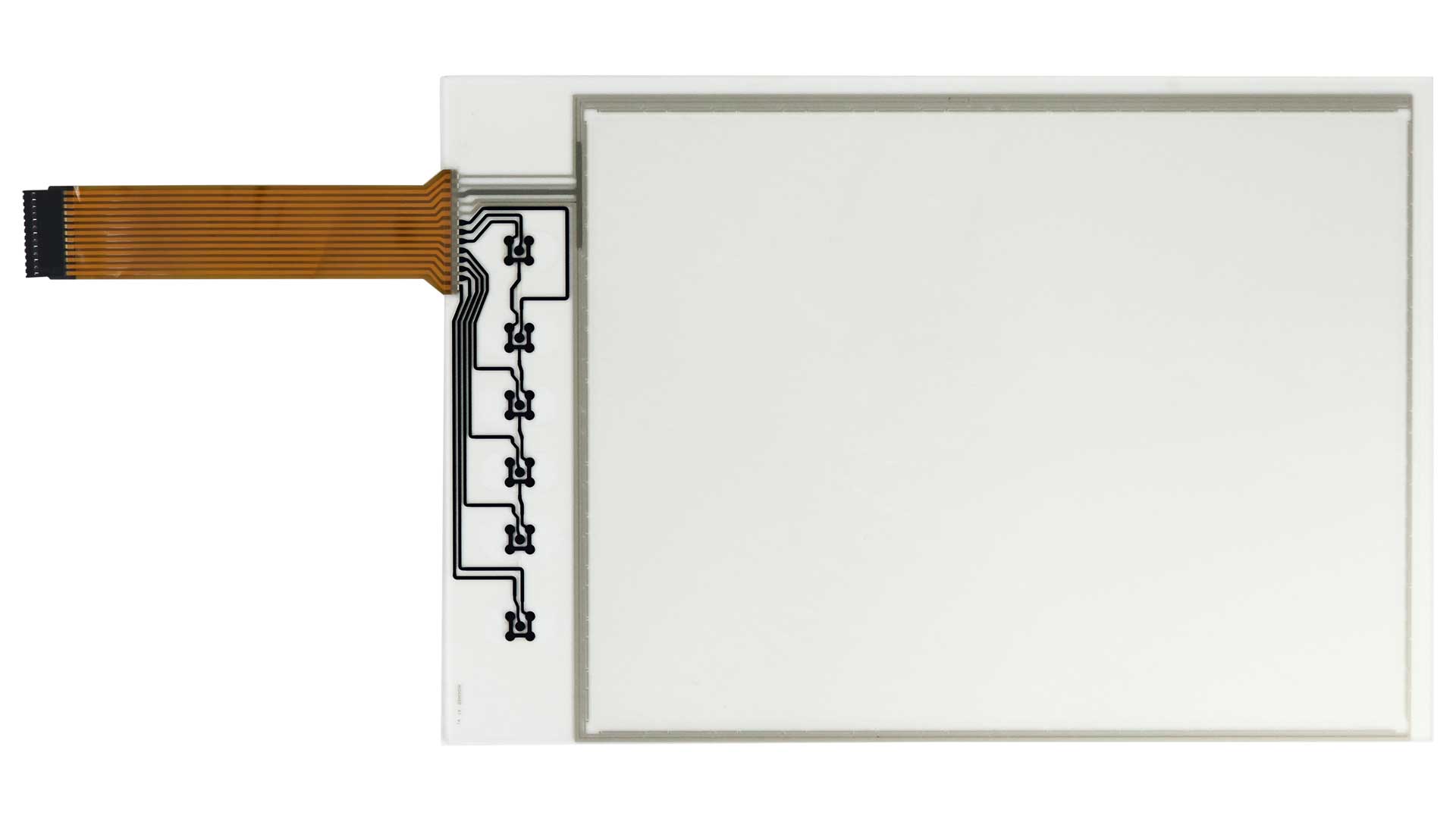

Digital matrix resistive touch screens are a type of touch screen technology that uses digital matrix technology. Digital matrix technology was used before analog resistive technologies such as 4-wire and 5-wire appeared, and was employed in factory automation, copying machines, faxes, phones, mobile games, calculators, cash dispensers, and more. The digital matrix technology utilized in resistive touch screens consists of top and bottom sheets with ITO coatings and electrodes arranged in stripes both horizontally and vertically. The top and bottom sheets face each other in a way that the striped ITO coatings bisect at right angles. When pressed, the intersections of the ITO coatings make contact, and these contacted points are detected as touch points. Each intersection of the ITO coatings functions as an independent switch, allowing for highly accurate touch detection. Digital matrix resistive touch screens remain popular today due to their low cost, durability, and high level of precision.