Compared with the traditional resistive touch screens with the highest market share at present, capacitive touch screens have brought many advantages to users, including: high light transmittance and more realistic color presentation, which give us better visual enjoyment; Users only need to slightly touch the screen or even do not need to actually touch it to operate the screen, which brings more relaxed and flexible experience to users; Capacitive touch screens have a longer service life, with a touch life of about 200 million times, 200 times that of 4-wire resistive touch screens (one million times) and five times that of 5-wire resistive touch screens (40 million times).

The signal detected by capacitive touch technology comes from the slight change caused by the touch action. According to different working principles, capacitive touch technology can be roughly divided into SCT (Surface Capacitive Touch) and PCT (Projected Capacitive Touch). The former is commonly applied in large-scale outdoor applications, such as public information platforms (POI) and public service (sales) platforms (POS), while the latter is rapidly popularized in consumer electronic products due to Apple’s multi-touch iPhone.

These two kinds of capacitive touch screens have the advantages of high light transmittance, fast reaction speed, long service life, etc. The disadvantages are as follows: with the change in temperature and humidity, the capacitance value will change, resulting in poor working stability, frequent touch-point drift that needs calibrations of the screen, and touching is unavailable when wearing ordinary gloves.

1. The working principle of Capacitive Touch Screens

Capacitive touch screens work by using the induction current of the human body. A coupling capacitor is formed between the user and the touch screen surface when the finger touches the metal layer due to the human electric field. For high-frequency current, this capacitor becomes a direct conductor that influences the overall capacitance characteristics of the circuit.

Advantages and disadvantages of capacitive touch screens

Advantages:

1. New experience in operation. Support multi-touch, direct operation, and more attractive.

2. Only need to be calibrated once or no need to be calibrated.

3. Higher durability, better dustproof, waterproof, wear-resistant performance, and other aspects.

Disadvantages:

1. The accuracy is not high.

2. Vulnerability to the environment.

3. The cost is relatively high.

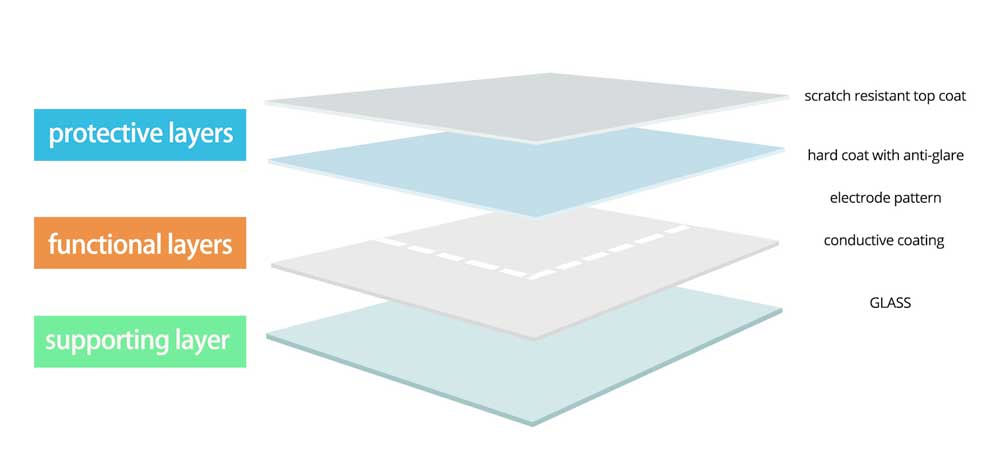

2. The Structure of SCT (Surface Capacitive Touch)

A capacitive touch screen is a four-layer composite glass screen. The inner surface of the cover glass and the interlayer are each coated with a layer of ITO. The two ITO layers are served as the active layers, which are shielded to ensure a good working environment, and four electrodes are led on the four corners. The outermost layer is a protective layer of silica glass. SCT has a simple working principle, low price, and simple circuit design, but it isn’t easy to realize multi-touch control.

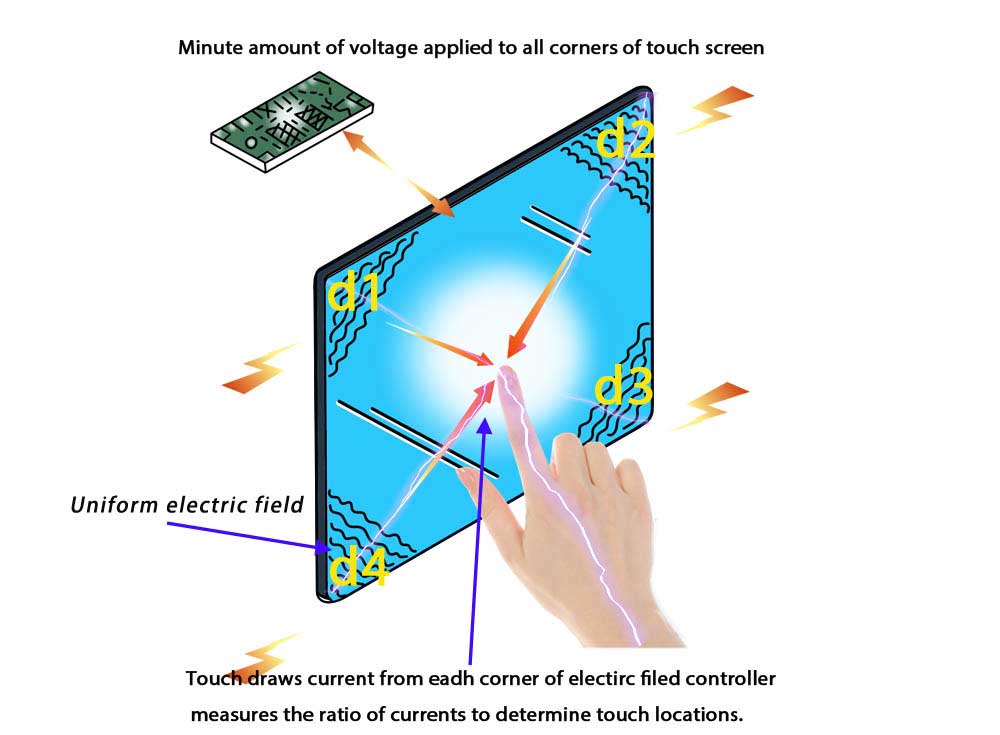

2.1 The Working Principle of SCT

When a finger touch the metal layer, a coupling capacitance will be generated between the finger and the surface of the touch screen due to the electric field of the human body. For high-frequency currents, the capacitance is a direct conductor. Thus, the finger draws a small current from the touch point. The current flows out of the electrodes on the four corners of the touch screen respectively, and the values of the current flowing through these four electrodes are proportional to the distance from the finger to the four corners. The controller can determine the touch point by calculating the precise ratio of the four currents.

2.2 Disadvantages of SCT

Disadvantages:

1. The transmittance of the four-layer composite touch screen with capacitive technology is not uniform for each wavelength of light, and there is color distortion. Due to the reflection of light between each layer, the image and characters will be blurred.

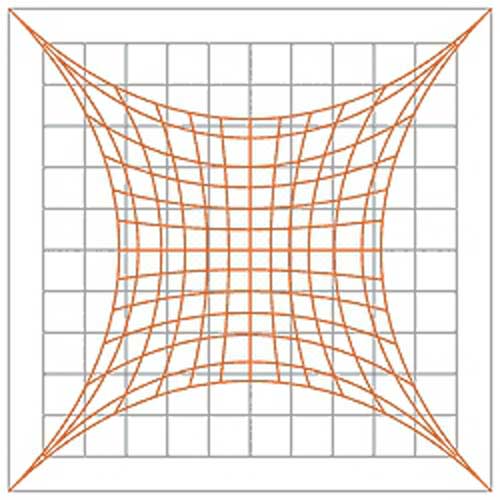

2. Uniformly deposited ITO will also cause pincushion distortion, which is usually corrected by a low-impedance edge pattern. For ITO coating of SCT, it is usually necessary to add linearized metal electrodes around the screen to reduce the influence of the corner/edge effect on the electric field.

3. Misoperation of the capacitive touch screen can be caused when a palm or hand-held conductor with a large area is close to the capacitive touch screen instead of touching it. This is especially serious in humid weather. When the display is held with your hand, the palm is within 7 cm of the display, or the body is within 15 cm of the display, misoperation of the capacitive touch screen may be caused.

4. When touching the screen with gloved hands or non-conductive objects, there is no response because more insulating media is placed.

5. When ambient temperature, humidity, or the ambient electric field changes, touch point drift will occur on the capacitive touch screen and cause inaccuracy.

6. The outermost layer of extremely thin glass has the characteristic of good scratch resistance under normal circumstances, but it is fragile.

3. Introduction to PCT (Projected Capacitive Touch)

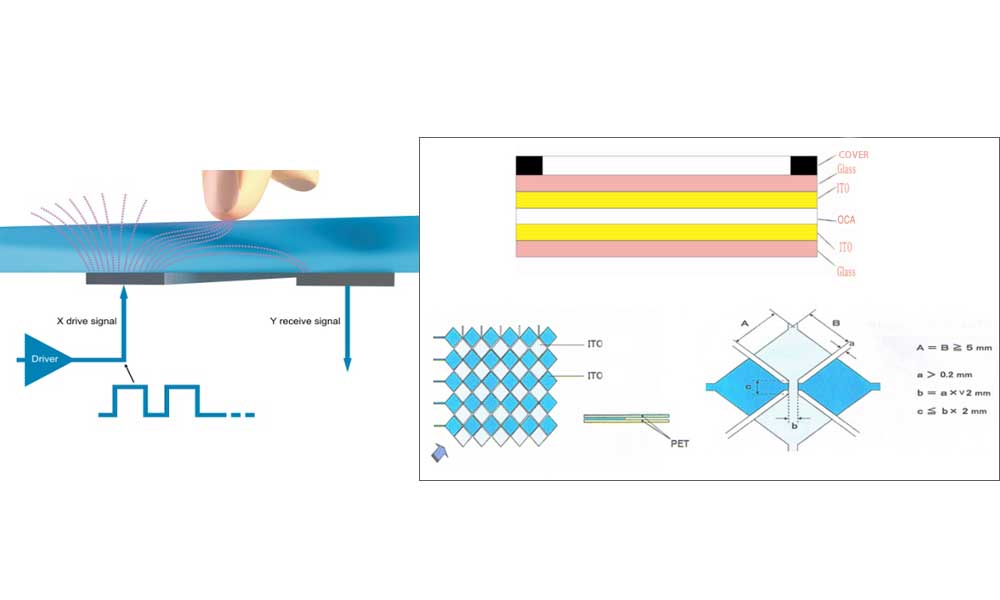

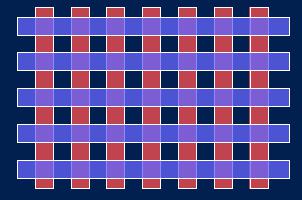

PCT screen has a multi-finger touch function. One or more carefully designed, etched ITO layers are required.

The ITO layer is etched to form a plurality of horizontal and vertical electrodes, all driven by a capacitive sensing chip. The chip can transfer data to the main processor and handle the X and Y axis position of touch points by itself.

Usually, both horizontal and vertical electrodes are driven by single-ended induction. In a word, there is no difference between one row and one column of driving circuits. We call this ‘single-ended’ induction (self-capacitance). However, in some schemes, a shaft is driven by a set of AC (Alternating Current) signals. Electrodes sense the response across the touch screen on other axes. This is called ‘transverse’ induction because the electric field passes across the dielectric layer of the upper panel from one electrode group (e.g., rows) to another electrode group (e.g., columns) (mutual capacitance).

4. The Working Principle of PCT-Self capacitive

An array of transverse and longitudinal electrodes is made of ITO (a transparent conductive material) on the surface of the glass. These transverse and longitudinal electrodes form capacitance to ground, respectively. This capacitance is commonly called self-capacitance, that is, the capacitance of electrodes to ground. When the finger touches the capacitive touch screen, the capacitance of the finger will be superimposed on the capacitance of the screen, which will increase the capacitance of the screen.

In touch detection, the transverse and longitudinal electrode arrays are respectively detected by the self-capacitive screen, and the transverse and longitudinal coordinates are respectively determined according to the change of capacitance before and after the touch, and then the plane touch coordinate is determined. The self-capacitance scanning method projects the touch points of the X-axis and Y-axis directions on the touch screen, respectively, and then calculates the coordinates in the X-axis and Y-axis directions, respectively. Finally, the coordinate of the touch point is determined by combining the X-axis and Y-axis coordinates.

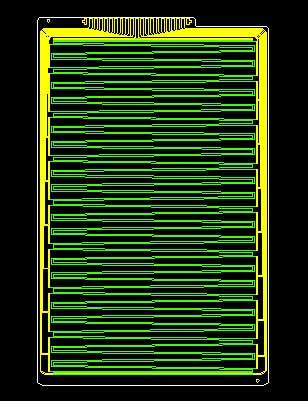

4.1 The Structure of PCT- Self capacitive

4.2 PCT – Self capacitive – ghost points

If it is a single touch, the projection in the X-axis and Y-axis directions is unique, and the combined coordinates are also one and only. If there are two touch points on the touch screen and these two points are not in the same X direction or Y direction, there will be two projections in the X and Y directions, respectively, and four coordinates are combined. Obviously, only two combined coordinates are valid, and the other two are commonly known as “ghost points”. Therefore, the self-capacitive screen cannot realize real multi-touch.

4.3 Disadvantages of PCT – Self capacitive

1. Calibration is required for the first time of use or when the environment changes significantly.

2. There is a “ghost point” effect, which makes multi-touch unrealizable.

There is a “ghost point” effect, which makes multi-touch unrealizable.

It is directly impacted by temperature, humidity, finger wetness, human body weight, and ground dryness. And it is also greatly interfered with by large external objects and is prone to have “touch point drift”.

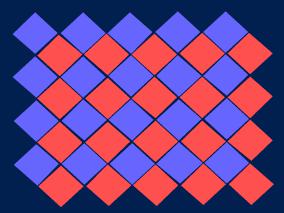

5. The Working Principle of PCT-Mutual capacitive

In terms of making transverse and longitudinal electrodes with ITO, the difference between mutual-capacitance and self-capacitance touch screens is that capacitance will be formed at which the two groups of electrodes intersect. In other words, the two groups of electrodes constitute the two electrodes of a capacitor, respectively.

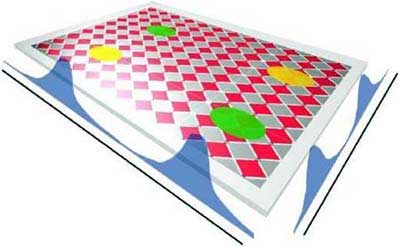

When the finger touches the capacitive touch screen, the coupling capacitance between the two electrodes near the touch point is influenced. Thus the capacitance value between the two electrodes is changed. When detecting the mutual capacitance, the transverse electrodes send excitation signals in turn, and all the longitudinal electrodes receive signals simultaneously. In this way, the capacitance values of all the intersection points of transverse and longitudinal electrodes, that is, the capacitance values of the two-dimensional plane of the whole touch screen, can be determined.

When the human finger touches the screen, the local capacitance will decrease. According to the touch screen’s two-dimensional capacitance change data, each touch point’s coordinates can be calculated. Therefore, even if there are multiple touchpoints on the screen, the true coordinates of each touch point can be calculated.

5.1 Structure of PCT-Mutual capacitive

5.2 Advantages of PCT – Mutual capacitive

1.No need for calibration.

2. The “ghost point” effect is avoided, and real multi-touch can be achieved.

3. It is not influenced by temperature, humidity, finger wetness, human body weight, ground dryness, and touch point drift will not occur.

6. Which is better, PCT (Projected Capacitive Touch) or SCT (Surface Capacitive Touch)?

The biggest difference between PCT (Projected Capacitive Touch Screen) and SCT (Surface Capacitive Touch Screen) is that PCT can support multi-touch, while SCT can only support single-touch. From this point of view, PCT seems to be superior to SCT, but in fact, it is not entirely so.

The working principle of PCT is not complicated, so it is not difficult to provide an exemplary prototype display. However, various technical challenges come one after another when engineers try to convert PCT Demo Set into a mass production plan to prepare for mass replication. The main challenges include the following three aspects.

1. The signal to be detected is weak. It is easily impacted by the environment and becomes unstable, which leads to inconsistent sensitivity of touch operation and may even cause mistouch. The change of capacitance caused by touching is highly susceptible to temperature and humidity. At present, the commonly used countermeasure is to use automatic timing calibration. In addition, other electrical appliances being used or other functions of the product itself, such as RF (Radio Frequency) of mobile phones, will also cause interference to signal measurement. This problem can be solved by improving SNR (signal noise ratio) by software or hardware; Up till now, IC designers still have space for effort in this aspect.

2. The pass rate for mass production needs to be improved. PCT technology has the inherent advantage of multi-touch. Therefore, since the launching of iPhone, almost all the focus has been on PCT. The whole touch screen industry, including touch screen manufacturers, IC design companies and solution developers, have invested a lot of resources to develop this technology. However, although there are many PCT products in the market, the overall production pass rate is still lower than SCT, resulting in the high cost. The reasons for the low pass rate are as follows: the existing PCT controller technology is still not mature enough, and the self-adjustment ability in different applications is still insufficient. Therefore, the touch menu is now unstable. In this case, the characteristics of PCT panel (such as resistance and capacitance within the panel, etc.) have to be strictly limited to reduce unstable factors. Due to the capability limitation of PCT controllers, the strict requirements for the consistency of PCT panel characteristics have often become the main reason for the low pass rate.

3. Patents. Because many basic gestures and multi-finger touch functions have been patented by some manufacturers and authorized, the multi-point advantages of PCT products cannot be brought into play in many application fields (especially the main mobile phone market)! On the whole, PCT scheme will definitely occupy the market in the future because of its advantages in multi-touch. However, according to the current situation, there is still much room for improvement.

In contrast, although SCT technology is faced with the problem that capacitor signals are vulnerable to interference in controller design, SCT scheme has been widely used in various environments through the continuous efforts of IC designers. For example, SCT Touch IC (WT5750F) developed by Weltrend Electronics and Wanda Optoelectronics can easily overcome the differences between various external environments and touch screen sizes by different adjustment mechanisms embedded in the IC, thus providing a stable and high-quality touch experience. In addition, to meet the needs of handheld devices for miniaturization, Weltrend Electronic has made great efforts to improve the integration in its SCT Touch IC. Therefore, it can meet the two critical demands of miniaturization and cost reduction at the same time.

Besides IC, the structure of SCT screen is simpler than PCT, and it is easier to overcome the problem of noise interference in hardware. In addition, through process improvement and breakthrough of crucial technologies, SCT overall solution has a competitive cost advantage compared to resistive touch screens. Taking the optical coating technology developed by Wanda Optoelectronics as an example, the light transmittance of touch screens can be increased from 87% to 97%, and the reflectivity can be reduced from 12% to 2%. More importantly, the pass rate of optical processing can be controlled above 90%, and outsourcing processing can be omitted. The technical autonomy and productivity can thus be improved, and the manufacturing cost can be greatly reduced.

As one of the capacitive touch technologies, SCT technology has also retained many advantages of capacitive touch screens, such as: “better visual enjoyment”, “easier and more flexible handling” and “longer service life”. In addition, SCT has relatively lower requirements for touch screen characteristics than PCT, and its mass production technology is more mature, enabling it with the advantages of a high pass rate and low cost simultaneously. Moreover, in practice, users’ demand for single-point selection, single-point gesture, and handwriting functions is more urgent than multi-touch. SCT can stably meet all these functional requirements. Therefore, before PCT solution matures (stable function, patent problems, high production pass rate, and low cost), SCT solution is a touch solution in line with market expectations.

At present, in the consumer electronic products market with a small size as the mainstream, there are only two choices of touch technology: resistive touch screen and PCT screen. Although the former is low in cost, the market has long criticized the poor optical performance and short serving life. PCT has many advantages, and many suppliers have realized its mass production. They are slightly more expensive than resistive screens and have been widely used in consumer electronic products.

Currently, SCT is rarely used in small-size products, mainly because of its high cost. SCT screen manufacturers have long lacked critical optical coating technology and have to outsource the processing. SCT touch IC is dominated by a few manufacturers, resulting in its continuous high price. In addition, unlike resistive screens that can be matched with resistive ICs at will, SCT screens must have excellent compatibility with ICs to work stably. All the factors mentioned above have made the price of SCT in small-size applications almost the same as PCT. Therefore, it can be challenging to be recognized by customers.

| Performance | Projected Capacitive Touch | Surface Capacitive Touch |

| Working principle | A coupling capacitance will be generated between the finger and the touch screen’s surface due to the human body’s electric field. For high-frequency currents, the capacitance is a direct conductor. Thus, the finger draws a small current from the touch point. The current flows out of the electrodes on the four corners of the touch screen respectively, and the values of the current flowing through these four electrodes is proportional to the distance from the finger to the four corners. The controller can determine the touch point by calculating the precise ratio of the four currents. –“Coupling capacitance” | It is an expansion of capacitive touch screens. An array of transverse and longitudinal electrodes is made of ITO (a transparent conductive material) on the surface of the glass. These transverse and longitudinal electrodes form capacitance to the ground (parasitic capacitance), respectively. When the finger touches the screen, the capacitance of the finger will change the parasitic capacitance of the touch screen, and the controller will determine the transverse and longitudinal coordinates of the touch point through this capacitance change. –“Coupling capacitance” + “Parasitic capacitance” |

| Application | 1. Game/ATM 2. Unable to achieve multi-touch 3. Mature technology and high cost 4. Inability to achieve full flat and borderless touch | 1.Small display terminals such as mobile phones/tablets/navigation products/digital cameras. 2.Multi-touch can be achieved 3.The cost is extremely high, especially for large-size products, and the performance is difficult to be controlled 4. Full flat and borderless touch |

| Operating voltage/current | Voltage: 5V, current: ≤ 50 mA | Voltage: 5V, current: ≤ 50 mA |

| Interface | RS-232 and USB | RS-232 and USB |

| Resolution | 1024*1024 | 2048*2048 |

| Induction shaft | X-axis, Y-axis | X-axis, Y-axis |

| Linearity | ≦±1.5%(X/Y axis) | ≦1MM |

| Drift | Existed | One calibration and no drift |

| Responding time | <8mS | <10mS |

| Interference | Prone to electromagnetic interference | Prone to electromagnetic interference |

| Stability | Normal | Good |

| Touch life | more than 2,250,000 single touches with no significant performance degradation | more than 2,000,000 single touches with no significant performance degradation. |

| Light transmittance | >85% | >88% |

| Touch method | Finger or capacitance pen | Finger or capacitance pen |

| Touch force | <50g, good feeling | <0.1g |

| Dirt influence | Small | Small |

| Anti-burst | Can be achieved, but cost increase is high | Temporarily not realizable |

| Operating temperature/humidity | Temperature: 0 ° C to + 70 ° C/Humidity: 5% ~ 80% RH | Temperature: -20 ° C ~ + 70 ° C/Humidity: 20% ~ 90% RH |

| Storage temperature/humidity | Temperature: -40 ° C to + 85 ° C/Humidity: 5% ~ 80% RH | Temperature: -30 ° C ~ + 80 ° C/Humidity: 20% ~ 90% RH |

| Working altitude | Altitude 4500M | Altitude 4500M |